In the ever-changing world of digital, screen, and pad printing, Boston Industrial Solutions, Inc., helps customers achieve precise and consistent ink color matching. Printing ink color plays a crucial role in conveying messages, marking products, and evoking emotions. Color is also critical in creating visually appealing designs. At Boston Industrial Solutions, Inc., we have mastered the art and science of ink manufacturing. Additionally, we offer a printing ink color matching service for customers who need custom colors. This enables contract printers to produce high-quality prints that meet their customers’ expectations.

At Boston Industrial Solutions, Inc., we offer unparalleled custom ink color matching services. Welcome to our ink world, where precision meets perfection! Our team of experts uses state-of-the-art technology to precisely match ink colors according to your needs. The meticulous color-matching process guarantees that every hue is reproduced with the utmost accuracy, leaving no room for compromise.

We custom blend inks in small or large batches for UV inks, screen printing inks, and pad printing inks according to PMS®, RAL®, HKS®, HEX, CMYK, RGB, or any color swatch that you provide.

Furthermore, we provide quick turnaround on all color matching service requests. We ship 98% of all custom color requests within 24 hours. Some of the industries that depend on our color matching services include automotive, aerospace, consumer electronics, medical devices, cosmetic packaging, promotional products, sporting goods, apparel, and power tool manufacturers. Many of the Fortune 500 companies and some of the largest promotional product companies use color-matched Natron® inks.

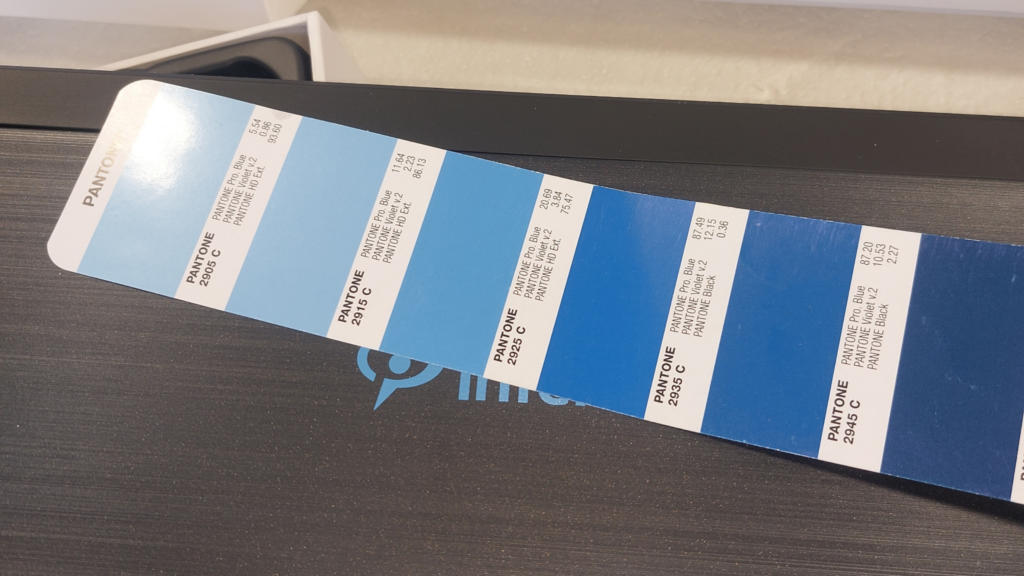

The Pantone Matching System (PMS) is a common, standardized color matching system in the printing industry. We use PMS swatch books to identify and match colors by referencing the PMS codes. To make sure colors are consistent from one batch to the next, we replace the PMS color swatches regularly.

Also, we use colorimeters and spectrophotometers to achieve accurate color representation. These tools enable us to analyze the spectral characteristics of light reflected from a surface. As a result, our experts objectively quantify color and make any necessary adjustments to achieve precise ink color reproduction.

Ink drawdowns are another tool we regularly use. This involves printing a small sample of ink on the substrate to visually check color accuracy. This hands-on approach to our color matching services reduces the chances of an error before the full print production run.

After creating the custom ink color formula, we store the colors in a digital database. This makes it easy to reproduce the same color when needed. Additionally, the digital database ensures absolute color consistency from one batch to the next. It also reduces waste and costs for the end user. Additionally, the database enables us to offer a quick turn-around screen and pad printing ink color matching service.

Color matching helps companies maintain a consistent brand image across many marketing materials. Many industrial and promotional companies use color matching to maintain a consistent brand image.

Additionally, accurate color matching demonstrates professionalism and attention to detail.

Perception is another important aspect of color matching ink for screen and pad printing. Color influences perception. Using the correct colors makes an item appealing, attractive, and more engaging.

Lastly, our printing color matching services help us minimize our customers’ ink waste and reduces the need for reprints due to color discrepancies.