Ink adhesion testing is the process of assessing the ability of an ink to permanently adhere to a substrate. This is one of the most essential ink services that we offer at no cost to you. Our ink adhesion services focus on printing ink for digital, screen, and pad printing processes.

At Boston Industrial Solutions, Inc., we understand that the adhesion of the ink or coating is crucial. Therefore, we make sure that prints made with our inks last for the life of the printed product. World-wide, many companies in various industries, such as promotional products, sporting goods, packaging, medical devices, aerospace, textiles, and manufacturing, rely on our adhesion testing services to ascertain that they have the best ink for marking and printing on products.

The turn-around time for adhesion testing services is 1-2 business days, depending on the substrate. We also offer a custom color matching service for inks

Different material surfaces vary in terms of texture and surface tension (energy). If the surface energy of the substrate is lower than that of the ink, the printing ink will not adhere to the material. Use a dyne pen to test the surface energy of a substrate. As a rule of thumb, the surface energy of the substrate should be equal to or greater than that of the ink for proper ink adhesion. The higher surface energy of the substrate allows for the printing, decoration, and marking of the product.

Always perform adhesion testing on all new products prior to high-volume printing.

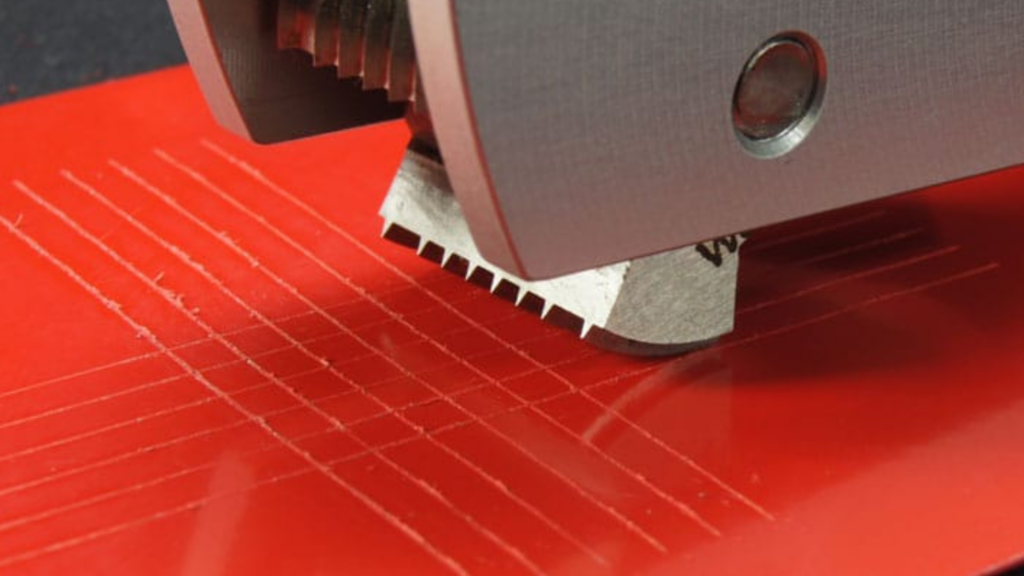

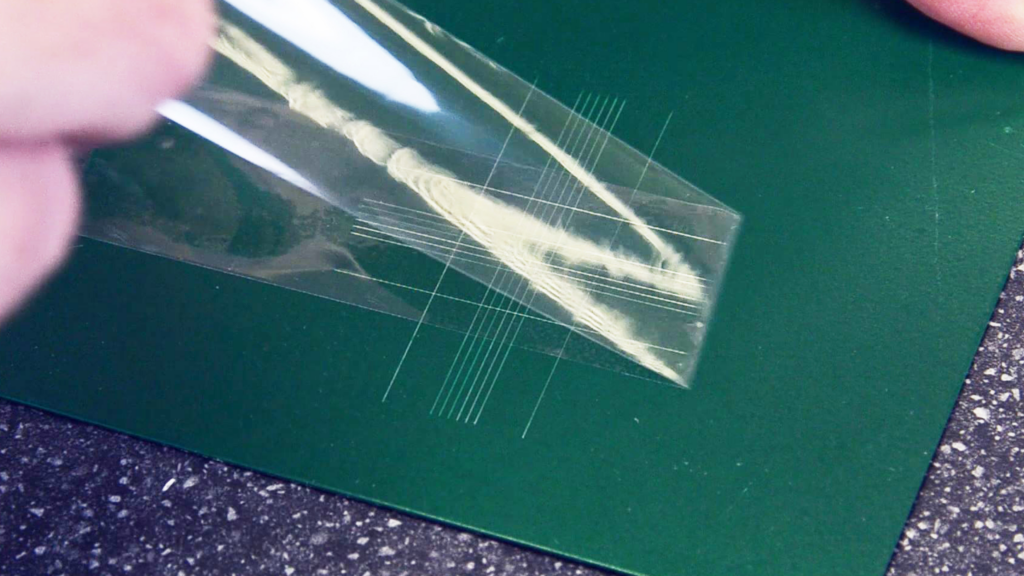

There are different methods for ink adhesion testing. The method depends on the specific requirements of the application. These testing methods are appropriate for UV ink, screen printing inks, and pad printing inks. Below are some common methods:

Our lab provides our customers with free silicone adhesion testing. Do you have an item that you find challenging to print? Do you have a product for which you are not sure if it is a silicone product? Send it to us. We will find a solution for you free of charge! We have a 24-hour turnaround for all our tests. Included as part of the free ink adhesion testing:

Finally, at Boston Industrial Solutions, Inc., we not only make and supply high-quality UV inks and screen and pad printing inks, but we also offer ink testing. In addition, we offer custom ink color matching and pad printing training services.

To request a free ink adhesion test, call +1 (781) 281-2558 or contact us today. Also visit our YouTube channel for the latest printing technologies.